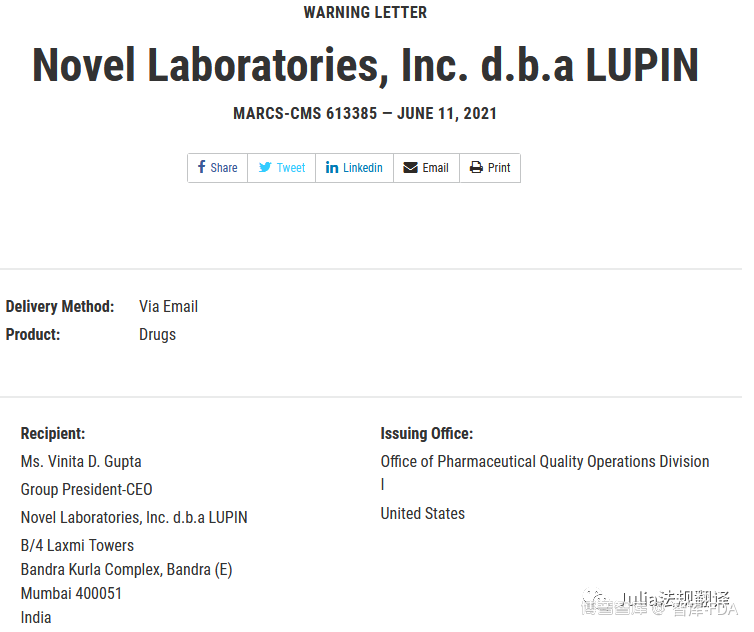

公司名称:Novel Laboratories, Inc.d.b.a. Lupin,美国新泽西

检查日期:2020-09-10至2020-11-05

产品:制剂

违规:场所CGMP违规,以及LUPIN多场所重复违规

签发:2021-06-11

发布:2021-06-29

Warning Letter

June 11, 2021

Dear Ms. Gupta:

The U.S. Food and Drug Administration (FDA) inspected your drug manufacturing facility, Novel Laboratories, Inc. d.b.a. Lupin, FEI 3006271438, at 400 Campus Drive, Somerset, New Jersey from September 10, 2020 to November 5, 2020.

This warning letter summarizes significant violations of current good manufacturing practice (CGMP) regulations for finished pharmaceuticals. See 21 Title Code of Federal Regulations (CFR), parts 210 and 211 (21 CFR parts 210 and 211).

Because your methods, facilities, or controls for manufacturing, processing, packing, or holding do not conform to CGMP, your drug products are adulterated within the meaning of section 501(a)(2)(B) of the Federal Food, Drug, and Cosmetic Act (FD&C Act), 21 U.S.C. 351(a)(2)(B).

We reviewed your November 30, 2020, response to our Form FDA 483 in detail and acknowledge receipt of your subsequent correspondence.

During our inspection, our investigators observed specific violations including, but not limited to, the following.

CGMP Violations

1. Your firm failed to establish and follow adequate written procedures for cleaning and maintenance of equipment (21 CFR 211.67(b)).你公司未建立并遵守充分的设备清洁和维护书面程序。(b)(4)(b)(4)

你们的非专用设备,包括压片机和XX的清洁程序不充分。我们的检查员发现一台压片机里面有之前生产的药品的残留,记录表明该设备为清洁状态并由质量部放行。你们使用该压片机生产几种高活性和非活性药品。

Investigators also observed residue on the(b)(4)(b)(4)(b)(4)(b)(4)

In your response, you stated that you performed analytical testing of the residue collected from the tablet press(b)(4)(b)(4)(b)(4)

检查员还发现你们的XX以及XX管上面有残留。你们2008年安装的XX设备清洁和预防性维护程序中没有这些区域的清洁指导,或者对风管进行定期检查。在你们的回复中,你们声称你们从压片机上采集了残留物进行了分析测试,确认有前一药品的活性药物残留。你们还说采集了XX的XX风管的残留物进行了检测,确认检出2种活性成分,甲氧苄啶和替硝唑。

Your response is inadequate because you did not test reserve samples of drug products released to the U.S. market and within expiry, that were manufactured on these pieces of non-dedicated equipment, for cross-contamination. You stated that the results of the(b)(4)(b)(4)

你们的回复不充分,因为你们没有检测在这些非专用设备上生产的,已放行到美国市场仍在效期内的药品的留样,是否受到交叉污染。你们声称XX残留结果低于你们的最大允许残留(MACO)限度,但是这并不能保证未发生交叉污染。此外,还发现残留上面有XX,此种情况无法保证完全防止交叉污染。

There is no assurance that you can prevent cross-contamination because your corrective action and preventive action (CAPA) plan fails to include cleaning the(b)(4)

In response to this letter, provide the following:

你们无法保证防止交叉污染,因为你们的CAPA计划未包括在更换产品时对XX风管进行清洁。回复本函时请提交以下内容:

• A commitment to test all reserve samples of drug products, within expiry and released to the U.S. market, that were manufactured on your tablet press and(b)(4)

承诺检测在上述所识别出的压片机和XX上生产的放行到美国市场且仍在有效期内的药品的所有留样,查看是否有交叉污染。你们的调查应该评估所有可能的污染来源。此外,检测应使用经过验证的方法,适合其用途,并证明药品具备其理当具备的含量、质量和纯度。提交一份检测结果汇总,其中应包括但不仅限于药品名称、批号、有效期、所执行的检测、检测方法名称、质量标准和检测结果。如果检测发现有药品质量不合格,则应快速采取措施,如通知客户和召回药品。

• A comprehensive, independent retrospective assessment of your cleaning effectiveness to evaluate the scope of cross-contamination hazards. Include the identity of residues, other manufacturing equipment that may have been improperly cleaned, and an assessment whether cross-contaminated drug products may have been released for distribution. The assessment should identify any inadequacies of cleaning procedures and practices and encompass each piece of manufacturing equipment used to manufacture more than one drug product.

一份对你们清洁效果的全面独立回顾性评估,评价交叉污染危害的范围。包括残留物鉴别,其它可能有不当清洁的生产设备,以及对受到交叉污染 的药品是否可能放行销售的评估。评估应该识别出清洁程序和做法的缺陷,包括用于生产不止一种药品的所有生产设备。

• A CAPA plan, based on the retrospective assessment of your cleaning and preventative maintenance programs, that includes appropriate remediations to your processes and practices, assessment of frequency, and timelines for completion. Provide a detailed summary of vulnerabilities in your process for lifecycle management of equipment cleaning and preventative maintenance. Describe improvements to these programs, including enhancements to effectiveness; improved ongoing verification of proper execution for all drug products and equipment; and all other needed remediations.

对你们清洁验证程序的恰当改进,要特别强调结合识别为药品生产操作中最差情形的条件。其中应包括但不仅限于识别和评估所有最差情形:o Drugs with higher drug potencies高活性药品o Drugs with characteristics that make them difficult to clean因其特性难清洁的药品o Residues for use in recovery studies回收率研究中所用残留物

• In addition, describe the steps that must be taken in your change management system before introduction of new manufacturing equipment or a new drug product.

此外还要说明引入新生产设备或新药品之前在你们变更管理系统中必须采取的措施

• A summary of updated SOPs that ensure an appropriate program is in place for verification and validation of cleaning procedures for drug products, processes, and equipment.

一份对更新后SOP的总结,确保具备恰当的药品、工艺和设备清洁程序的核查和验证程序

2. Your firm failed to establish adequate written procedures for production and process control designed to assure that the drug products you manufacture have the identity, strength, quality, and purity they purport or are represented to possess (21 CFR 211.100(a)).你公司未能建立足够的书面生产和工艺控制程序,用于确保你们生产的药品具备其理当具备的成分、含量、质量和纯度。

You failed to adequately validate the manufacturing processes for temazepam 15mg and 30mg capsules before the transfer of product manufacturing to a new building. You did not adequately assess the process and equipment changes (e.g., charging order of the active pharmaceutical ingredient, different model(b)(4)

你未能在将生产转移至新厂房之前对替马西泮15mg 和 30mg胶囊进行充分的生产工艺验证。你们未充分评估对你们生产操作所做的工艺和设备变更(例如,API投料顺序,不同的XX型号),未识别出其对产品质量的影响。你们实施这些变更之后生产了若干批次,并放行至美国市场。使用这些未经的变更生产的几个批次含量均匀度不合格(OOS)。

Your OOS results suggest that your process is not robust. You did not adequately demonstrate that your manufacturing processes are reproducible and controlled to consistently yield drugs of uniform character and quality.

你们的OOS结果显示你们的工艺不稳健。你们并未充分证明你们的生产工艺可重复并受控,可持续产出具有均一特性和质量的药品。

In your response, you stated that you recognized the occurrence of suboptimal process performance for your temazepam capsule manufacturing operations, which was the root cause of the OOS results. You also stated that you completed a(b)(4)(b)(4)

在你们的回复中,你们声称你们认识到你们替马西泮胶囊生产操作的工艺表现不够优化,并反复发生,这是OOS结果的根本原因。你们还说你们已完成了XX批15mg和30mg剂量验证研究,使用的是已实施的设备和工艺变更,所有批准均符合标准。此外,你们还说你们已启动了持续工艺监测核查取样方案,用于监测改进后生产XX批次的含量。

Your response is inadequate because you did not provide assurance that the batches released to the U.S. market, manufactured before validation, are of the appropriate strength and quality. The additional content uniformity testing performed for these batches does not ensure that all other product quality attributes are in conformance.

In addition, your firm does not have an adequate ongoing program for monitoring process control to ensure stable manufacturing operations and consistent drug quality. Your continuous process monitoring verification sampling protocol only assesses dose uniformity. Out-of-trend (OOT) results for assay were identified when you made changes to manufacturing operations at the time of product transfer.https://www.fda.gov/media/71021/download.

参见FDA指南文件:工艺验证通则和规范。

In response to this letter, provide the following:

在回复本函时请提交

• A detailed summary of your validation program for ensuring a state of control throughout the product lifecycle, along with associated procedures. Include your validation report, continuous process monitoring verification sampling protocol for temazepam 30mg, and risk assessment reports for temazepam 15mg and 30mg. Describe your program for process performance qualification, and ongoing monitoring of both intra-batch and inter-batch variation to ensure a continuing state of control.

一份对你们验证程序的详细总结,确保在整个产品生命周期的受控状态,连同相关程序一起提交。其中要包括你们的替马西泮30mg验证报告、持续工艺监测核查取样方案,和替马西泮15mg与30mg风险评估报告。说明你们的工艺性能确认程序,和批间与批内波动的持续监测,确保持续受控状态

• A timeline for performing appropriate process performance qualification for each of your marketed drug products.

一份对所有上市药品实施适当工艺性能确认的时间表

• Improved in-process testing and monitoring to enhance detection of variation during production of each batch. Include remediated in-process quality standards, including but not limited to enhanced sampling, that will more robustly monitor upstream process control. Describe how the improvements will ensure early detection of process variation and manufacturing defects, and prevent consumer exposure to substandard quality drug products.

为提高各批生产期间的波动情况检测能力而改进后和中控检测和监测。包括经过补救的中控质量标准,包括但不仅限于改进后的取样,使得上游工艺控制更为稳健。说明这些改进是如何确保在早期发现工艺波动和生产缺陷,并防止消费者暴露于不合格的药品的。

3. Your firm failed to establish and follow adequate written responsibilities and procedures applicable to the quality control unit (21 CFR 211.22(d)).你公司未为质量部门建立并遵守足够的书面职责和程序。

Your quality unit (QU) failed to adequately establish and adhere to written procedures to ensure the strength, quality, and purity of the drug products you manufacture. For example,

你们的质量部门(QU)未建立并遵守书面程序,确保你们生产的药品的含量、质量和纯度。例如

• Your cleaning validation protocol procedure for the review and approval to change the MACO limits did not require adequate QU oversight. Specifically, this procedure did not require QU review of the test methods and the approved cleaning MACO limits, for potent and non-potent drug products manufactured on non-dedicated equipment. You did not ensure that each of these test methods had the capability to quantitate the newly established limits.

你们供审批的清洁验证方案程序修改了MACO限度,但并未要求足够的QU监管。具体来说,该程序并未要求QU审核在非专用设备上生产的高活性和低活性药品的检测方法和已批准的MACO限度。你们未确保每项检测均有能力对新建立的限度进行定量检测。

• You failed to adequately complete annual product reviews (APR) as required by 211.180(e) and your established procedure. Several drug products with a 2019 APR due date remained pending at the time of inspection. Your procedure required APR completion within(b)(4)

你们未按211.180(e)和你们既定程序的要求圆满完成年度产品回顾(APR)。有几个产品的2019年APR在检查时已超期但还没有定稿。你们的程序要求APR在产品的年度日期XX内完成。

Your firm previously made corporate-wide commitments to strengthen analytical method equivalency, cleaning validation procedures, and APR procedures across all sites and to have corporate quality assurance oversight of these areas.

你公司之前做出全球承诺,要强化所有场所的分析方法等同性、清洁验证程序和APR程序,并要求公司级质量部门对此进行监管。

In your response, you stated that you acknowledged a need for more robust QU oversight of your cleaning validation program and have revised your procedure,SOP NL-VA-002, Cleaning Validation and Verification Procedureto include a risk assessment and method impact assessment. You also identified that laboratory management, and not your QU, has the authority to review and approve individual standard operating procedures (SOP) pertaining to test method validations. You stated that these SOPs are being harmonized for alignment and consistent execution. In addition, you stated that individuals primarily responsible for APR are also responsible for additional QU tasks and that the(b)(4)(b)(4)

在你们的回复中,你们声称你们知晓需要对你们的清洁验证程序进行更为强有力的QU监管,已修订了你们的程序SOP NL-VA-002清洁验证和核查程序,在其中加入了风险评估和方法影响性评估。你们还识别出实验室管理(不是你们的QU)有权力审核和批准单个检测方法验证SOP。你们声称这些SOP已经统一化,并统一实施了。另外,你们声称负责APR的人员亦负责其它QU工作,表式流程已采用XX系统替代。

Your response is inadequate because you failed to provide a comprehensive assessment of all written procedures to ensure that procedures impacting the identity, strength, quality, and purity of the drug products manufactured, grant the responsibility of approval to the QU.

你们的回复不够,因为你们未提交一份所有书面程序的全面评估,确保影响所生产药品的成分含量、质量和纯度的程序均由QU批准。

Significant findings as detailed in this letter indicate that your QU is not fully exercising its authority and/or responsibilities. Your firm must provide the QU with the appropriate authority and sufficient resources to carry out its responsibilities and consistently ensure drug quality.

In response to this letter, provide the following:

本函中所述的严重缺陷显示你们的QU未履行其权力和/或职责。你公司必须为QU提供恰当的权力和足够的资源,让其履责,并持续确保药品质量。在回复本函时,请提交以下资料

• A comprehensive assessment and remediation plan to ensure your QU is given the authority and resources to effectively function. The assessment should also include, but not be limited to:

一份全面评估和补救计划,确保赋予你们QU权力和资源,可有效运转。该评估还应包括但不仅限于

确定你公司所用程序是否稳健和恰当

确定你们的QU是否具备足够的教育背景、培训和经验,或这些组合,有能力实施其所被赋予的QU职责

QU对整个操作进行监管的条款,评估是否遵守恰当的规范

QU做出处置决定之前对每个批次及其相关信息进行完整和最终审核

• Also describe how top management supports quality assurance and reliable operations, including but not limited to timely provision of resources to proactively address emerging manufacturing/quality issues and to assure a continuing state of control.

还要说明高级管理层如何支持质量保证和可靠操作,包括但不仅限于及时提供主动解决新发生产/质量问题并保证持续受控状态的资源

Repeat Violations at Multiple Sites多场所重复违规

FDA在你公司旗下此场所中发现相似的CGMP违规

• On September 10, 2019, Lupin Limited Mandideep (Unit 1), FEI 3002807511, was issued a warning letter for violation of, among other items, 21 CFR 211.67(a) for inadequate cleaning of manufacturing equipment and 21 CFR 211.100(a) for inadequate process validation.

20190910,Lupin Mandideep (Unit 1), FEI 3002807511被签发警告信,其中缺陷有21 CFR 211.67(a)生产设备清洁不够,和21 CFR 211.100(a)生产工艺验证不够。

• On November 6, 2017, Lupin Limited Goa (FEI 3004819820) and Lupin Limited Indore (FEI 3007549629), were issued a warning letter for CGMP violations and in response made corporate-wide commitments to strengthen corporate quality compliance and global quality governance.

20171106,LUPIN GOA(FEI 3004819820)和Lupin Indore (FEI 3007549629)被签发CGMP警告信,回复中承诺要加强公司质量合规和全球质量管理

Repeated violations at multiple sites demonstrate that your company’s corporate oversight and control over the manufacture of drugs is inadequate. You should further comprehensively assess your company’s global manufacturing operations to ensure that systems and processes, and ultimately, the drug products manufactured, conform to FDA requirements at all your sites.

多场所重复违规说明你公司对药品生产的监管和控制不够。你们应该进一步全面评估你公司的全球生产操作,确保你们所有场所的系统和工艺,最终确保所生产的药品符合FDA要求。

Conclusion

The violations cited in this letter are not intended to be an all-inclusive list of violations that exist at your facility. You are responsible for investigating and determining the causes of these violations and for preventing their recurrence or the occurrence of other violations.

Correct any violations promptly. Failure to promptly and adequately address this matter may result in regulatory or legal action without further notice including, without limitation, seizure and injunction. Unresolved violations may also prevent other Federal agencies from awarding contracts.

Failure to address violations may also cause FDA to withhold issuance of Export Certificates. FDA may withhold approval of new applications or supplements listing your firm as a supplier or drug manufacturer until any violations are completely addressed and we confirm your compliance with CGMP. We may re-inspect to verify that you have completed corrective actions to address any violations.

This letter notifies you of our findings and provides you an opportunity to address the above deficiencies. After you receive this letter, respond to this office in writing within 15 working days. Specify what you have done since our inspection to correct your violations and to prevent their recurrence. In response to this letter, you may provide additional information for our consideration as we continue to assess your activities and practices. If you cannot complete corrective actions within 15 working days, state your reasons for delay and your schedule for completion.

Send your electronic response to orapharm1_responses@fda.hhs.gov. Your written notification should refer to Warning Letter CMS # 613385 and include FEI: 3006271438.

If you have any questions, contact Compliance Officer BarbaraWilimczyk-Macri at barbara.wilimczyk@fda.hhs.gov or 973-331-4951.

Sincerely,

Diana Amador-ToroOffice of Pharmaceutical QualityOperations Division I/

Cc:Vice President-Operations and Site Head400 Campus DriveRonaldOverhiser@lupin.com