转发本文到朋友圈,添加微信pckt6842 免费领取【供应商管理规程】

点击链接,查看平台1000+供应商相关资料,文末更有优质资源推荐哦~

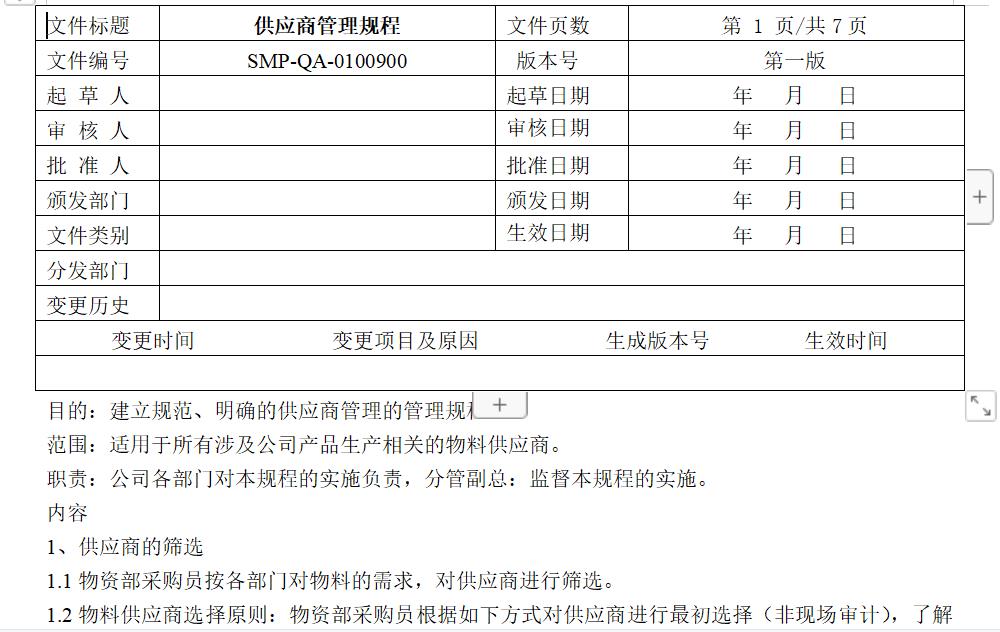

( 供应商管理)

供应商管理)

1. 基本概念

供应商管理(Supplier),物料供应商的管理包含:文件上的要求(如:建立供应商管理的程序,内容至少涵盖供应商的评估、审计、批准、撤销等;批准的供应商清单;建立供应商档案等);定期的现场审计、评估,并形成审计报告;供应商变更的管理(如:进行小批量试生产,现场审计,进行稳定性考察等);与主要物料供应商签订质量协议;定期的质量回顾分析。

2. 相关法规

2.1 中国GMP 第十章 质量控制与质量保证( 中国GMP 第十章 质量控制与质量保证)

中国GMP 第十章 质量控制与质量保证)

第七节 供应商的评估和批准

第二百五十五条 质量管理部门应当对所有生产用物料的供应商进行质量评估,会同有关部门对主要物料供应商(尤其是生产商)的质量体系进行现场质量审计,并对质量评估不符合要求的供应商行使否决权。

主要物料的确定应当综合考虑企业所生产的药品质量风险、物料用量以及物料对药品质量的影响程度等因素。

企业法定代表人、企业负责人及其他部门的人员不得干扰或妨碍质量管理部门对物料供应商独立作出质量评估。

2.2 药用辅料生产质量管理规范( 药用辅料生产质量管理规范)

药用辅料生产质量管理规范)

第二十六条 应检查、评估供应商的综合能力,确保原料、包装材料以及服务满足合同的要求。

第二十七条 应制定辅料生产所用物料购入、储存、发放、使用等管理制度。物料应有质量标准,企业应按质量标准对物料进行检验,并审核供应商的检验报告,以确保物料的规格和质量满足辅料生产的质量要求。

2.3 FDA CFR 211.84 Testing and approval or rejection of components, drug product containers, and closures.( FDA CFR 211.84 Testing and approval or rejection of components, drug product containers, and closures.)

FDA CFR 211.84 Testing and approval or rejection of components, drug product containers, and closures.)

(d)(2) Each component shall be tested for conformity with all appropriate written specifications for purity, strength, and quality. In lieu of such testing by the manufacturer, a report of analysis may be accepted from the supplier of a component, provided that at least one specific identity test is conducted on such component by the manufacturer, and provided that the manufacturer establishes the reliability of the supplier's analyses through appropriate validation of the supplier's test results at appropriate intervals.

(3) Containers and closures shall be tested for conformity with all appropriate written specifications. In lieu of such testing by the manufacturer, a certificate of testing may be accepted from the supplier, provided that at least a visual identification is conducted on such containers/closures by the manufacturer and provided that the manufacturer establishes the reliability of the supplier's test results through appropriate validation of the supplier's test results at appropriate intervals.

2.4 FDA CFR 211.184 Component, drug product container, closure, and labeling records.( FDA CFR 211.184 Component, drug product container, closure, and labeling records.)

FDA CFR 211.184 Component, drug product container, closure, and labeling records.)

These records shall include the following:

(a) The identity and quantity of each shipment of each lot of components, drug product containers, closures, and labeling; the name of the supplier; the supplier's lot number(s) if known; the receiving code as specified in 211.80; and the date of receipt. The name and location of the prime manufacturer, if different from the supplier, shall be listed if known.

2.5 EU GMP Chapter 5 Production( EU GMP Chapter 5 Production)

EU GMP Chapter 5 Production)

Starting materials

5.27 The selection, qualification, approval and maintenance of suppliers of starting materials, together with their purchase and acceptance, should be documented as part of the pharmaceutical quality system. The level of supervision should be proportionate to the risks posed by the individual materials, taking account of their source, manufacturing process, supply chain complexity and the final use to which the material is put in the medicinal product. The supporting evidence for each supplier / material approval should be maintained. Staff involved in these activities should have a current knowledge of the suppliers, the supply chain and the associated risks involved. Where possible, starting materials should be purchased directly from the manufacturer of the starting material.

5.28 The quality requirements established by the manufacturer for the starting materials should be discussed and agreed with the suppliers.

Appropriate aspects of the production, testing and control, including handling, labelling, packaging and distribution requirements, complaints, recalls and rejection procedures should be documented in a formal quality agreement or specification.

5.29 For the approval and maintenance of suppliers of active substances and excipients, the following is required:

Active substances

Supply chain traceability should be established and the associated risks, from active substance starting materials to the finished medicinal product, should be formally assessed and periodically verified. Appropriate measures should be put in place to reduce risks to the quality of the active substance.

The supply chain and traceability records for each active substance (including active substance starting materials) should be available and be retained by the EEA based manufacturer or importer of the medicinal product.

Audits should be carried out at the manufacturers and distributors of active substances to confirm that they comply with the relevant good manufacturing practice and good distribution practice requirements. The holder of the manufacturing authorisation shall verify such compliance either by himself or through an entity acting on his behalf under a contract. For veterinary medicinal products, audits should be conducted based on risk.

Audits should be of an appropriate duration and scope to ensure that a full and clear assessment of GMP is made; consideration should be given to potential cross- contamination from other materials on site. The report should fully reflect what was done and seen on the audit with any deficiencies clearly identified. Any required corrective and preventive actions should be implemented.

Further audits should be undertaken at intervals defined by the quality risk management process to ensure the maintenance of standards and continued use of the approved supply chain.

Excipients

Excipients and excipient suppliers should be controlled appropriately based on the results of a formalised quality risk assessment in accordance with the European Commission ‘Guidelines on the formalised risk assessment for ascertaining the appropriate Good Manufacturing Practice for excipients of medicinal products for human use.

5.30 For each delivery of starting material the containers should be checked for integrity of package, including tamper evident seal where relevant, and for correspondence between the delivery note, the purchase order, the supplier's labels and approved manufacturer and supplier information maintained by the medicinal product manufacturer. The receiving checks on each delivery should be documented.

2.6 WHO GMP 8.Self-inspection and quality audits( WHO GMP 8.Self-inspection and quality audits)

WHO GMP 8.Self-inspection and quality audits)

8.8 The person responsible for quality control should have responsibility together with other relevant departments for approving suppliers who can reliably supply starting and packaging materials that meet established specifications

8.9 Before suppliers are approved and included in the approved supplier's list or specifications , they should be evaluated. The evaluation should take into account a supplier's history and the nature of the materials to be supplied. If an audit is required, it should determine the supplier's ability to conform with GMP standards.

2.7 FDA指南

制药用气体供应商

If the testing is not witnessed and the HCC chooses to rely on a valid COA, the Agency recommends that the HCC perform a specific identity test. The HCC would also periodically verify the reliability of the supplier's analysis. This can be done by (1) visiting the supplier to verify that the supplier is following appropriate written testing procedures, (2) observing the supplier’s analytical testing, including calibration of the analyzer, and (3) documenting that steps 1 and 2 have been taken. Alternatively, to periodically verify the reliability of the supplier’s analysis, the HCC can submit to a third party a sample from a recent delivery to be analyzed for conformance with the USP requirements or established specifications.

ANDA申请变更原料药供应商

Applicants should submit an amendment to their pending application requesting the withdrawal of the primary API supplier with the supporting information to add the new supplier just as is expected for any supplier of an API.

3.资源推荐

优质课程

从法规到应用,掌握物料风险评估的正确方法

制药人必看-原辅料供应商审计

资源专栏

药企必备:供应商管理相关资料

优秀文章

供应商管理应用分享

药品物料供应商的管理细则及注意事项

供应商管理必看 - 问答实操工作集锦